The Important Overview to Understanding Screen Printing and Its Versatile Uses

Screen printing has an abundant history that goes back to ancient times, developing into a sophisticated strategy used throughout different sectors today. This overview checks out the intricacies of the screen printing procedure, detailing its applications in home, advertising and marketing, and style décor - 10:9 Design Company. Recognizing these fundamentals can open up imaginative potential for both creative and business projects. The complying with areas will disclose important pointers and techniques to improve one's screen printing undertakings

The History of Screen Printing

Although screen printing has roots that map back centuries, its advancement reflects the technological and creative advancements of different societies. Coming from ancient China, the method was originally made use of for enhancing fabrics and later infect Japan, where it became essential to Ukiyo-e woodblock printing. The technique shifted to Europe in the 18th century, where it obtained appeal amongst craftsmens and business printers. The creation of image solution in the 20th century revolutionized screen printing, enabling even more detailed layouts and better effectiveness. Artists like Andy Warhol even more pushed its appeal, utilizing the medium to create famous jobs that combined commercialism and art. By the late 20th century, screen printing had established itself as a functional strategy, used in style, advertising and marketing, and great art. Today, it remains to develop, integrating electronic innovation and broadening its applications across various industries.

The Screen Printing Refine Explained

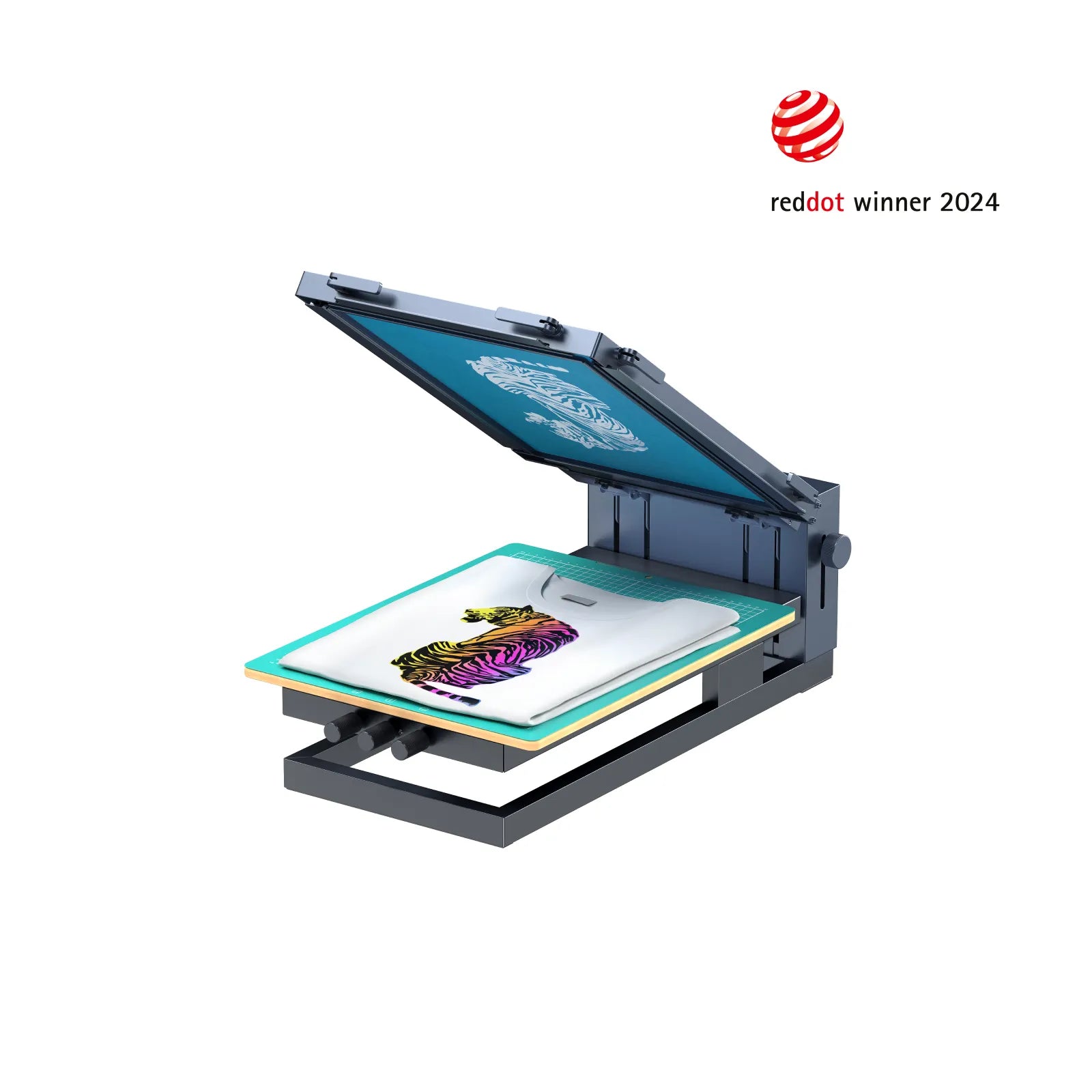

Screen printing changes creative visions into substantial layouts via a collection of accurate steps. Initially, a picture is created and after that moved onto a screen, usually made of great mesh material stretched over a structure. A light-sensitive emulsion is related to the screen, which is exposed to light, setting in areas not covered by the photo. After rinsing the unhardened emulsion, a pattern is formed.

Next off, the screen is put over the substratum, whether it be material, paper, or an additional material. Ink is after that pushed via the open areas of the pattern utilizing a squeegee, depositing the layout onto the substrate listed below. This process can be duplicated for multiple shades, requiring different screens for every hue. The published thing is cured utilizing warmth to ensure the ink sticks correctly, resulting in a long lasting, vibrant style all set for use.

Kinds of Screen Printing Techniques

Additionally, specialized methods, such as discharge screen printing, get rid of dye from the fabric to produce softer prints, while foil screen printing applies metal foil to attain a shiny coating (10:9 Design reviews). Each technique uses distinct qualities, accommodating numerous imaginative requirements and manufacturing scales, eventually expanding the opportunities within the screen printing domain

Applications of Screen Printing in Different Industries

Additionally, the signs and marketing industries make use of screen printing for creating distinctive displays and banners. This technique enables for vibrant colors and detailed designs that catch interest. In electronics, screen printing is utilized for using conductive inks to motherboard, essential for element links. The home design market accepts screen printing to create distinct layouts on fabrics and wall surface art. Overall, screen printing functions as a vital device throughout varied areas, boosting items with individualized and aesthetically enticing graphics.

Tips for Effective Screen Printing Projects

While undertaking a screen printing project, careful attention to detail can significantly boost the final outcome. Selecting high-quality materials is crucial; this includes the screen, inks, and substrates. Using appropriate mesh counts can influence ink deposition and detail resolution. Preparation is equally important; thorough cleansing of displays and proper exposure times assure crisp prints.

Next off, precise registration is crucial the original source for multi-color prints. Making use of placement tools can help achieve specific layering. In addition, testing prints on scrap products prior to manufacturing assists determine potential problems without losing resources.

Often Asked Questions

What Products Are Best for Screen Printing on Fabric?

Cotton and polyester blends are optimal for screen printing on material because of their longevity and ink absorption. In addition, specialized textiles like silk or canvas can generate special appearances and surfaces, improving the general layout top quality.

Just how Do I Clean and Maintain Screen Printing Devices?

To clean and maintain screen printing tools, one need to regularly clean displays with ideal solvents, inspect mops for wear, lube moving parts, and shop all products in a dry, dust-free environment to lengthen their life-span.

What Are the Environmental Impacts of Screen Printing?

Screen printing can have substantial environmental effects, including chemical waste from solvents and inks, water use during cleaning procedures, and energy consumption. Environmentally friendly products and lasting methods are crucial for decreasing these unfavorable effects.

Can Screen Printing Be Done in the house Efficiently?

Screen printing can be successfully done at home with the ideal materials and techniques. Hobbyists can produce quality prints, though success depends upon their skill degree, equipment, and understanding of the procedure involved.

What Are the Expenses Connected With Beginning a Screen Printing Organization?

Beginning a screen printing company includes prices for equipment, materials, and office. First expenses usually vary from a couple of hundred to numerous thousand dollars, depending upon the scale, high quality of equipment, and wanted production capacity.

Screen printing has a rich history that dates back to old times, evolving into an advanced method utilized throughout numerous industries today. One more method, rotary screen printing, utilizes round displays, assisting in continuous printing on fabric rolls, thus improving effectiveness for large-scale productions. Additionally, specialty techniques, such as discharge screen printing, remove dye from the fabric to create softer prints, while foil screen printing applies metal aluminum foil to accomplish a shiny coating. In the style field, screen visit this site printing is commonly made use of to develop vivid layouts on clothing, allowing brand names to showcase their unique designs. Cotton and polyester blends are ideal for screen printing on textile due to their durability and ink absorption.